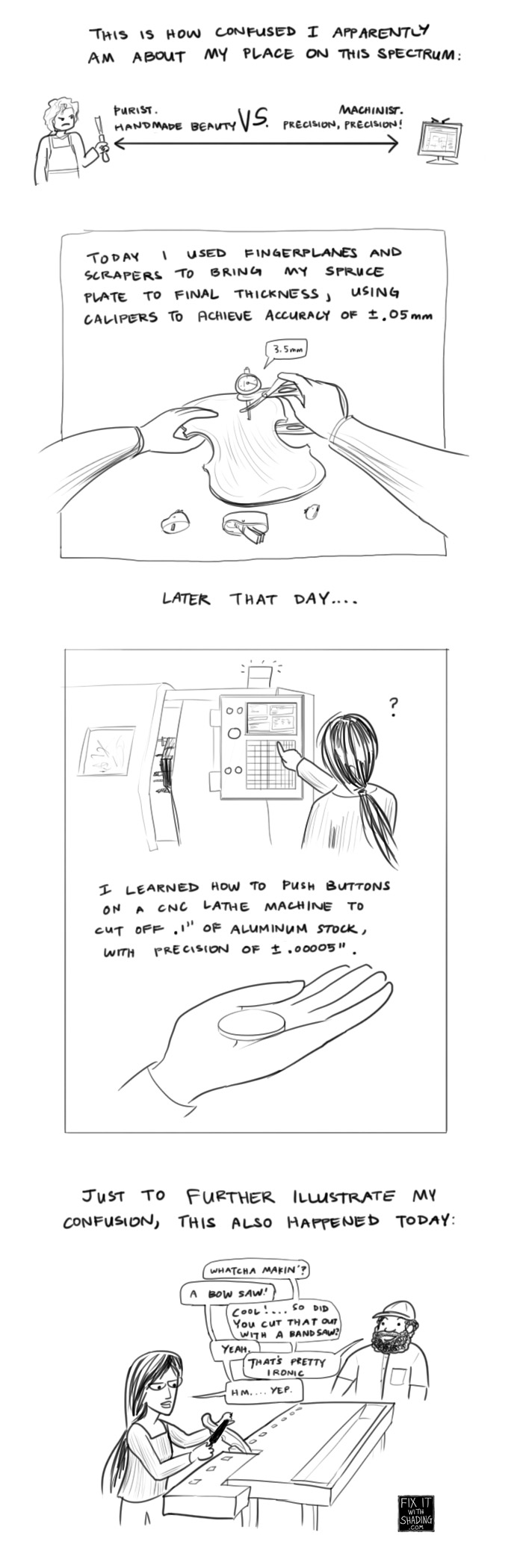

So this week, I began evening classes at Symbol Training to learn how to operate CNC machines. Quite the opposite end of the spectrum from violin making school, where I am not even allowed to touch the bandsaw. I don’t specifically know what I intend to do with all this training in architecture/design, fine woodworking, and CNC, but it sounds like a good combo for making something really awesome one day. Maybe. But pshh, do I really have to pick a side anyway?? I didn’t think so.

And now, some photographic proof to corroborate the claims made in above illustrations:

This is my spruce plate after it was attacked by a fleet of little round-bottom finger planes. It is about .2mm away from final dimensions here, and I will scrape it to achieve the final thickness.

It’s unsettling at first, but quite a bit of light passes through that piece of spruce as it approaches final thickness. Take that, Alice Tully Hall!

This coin, which I cut off from a cylindrical stock of aluminum spinning in the lathe (Manual Direct Input! T02 S1500 M03! Insert! Hand jog, .001, x-axis!), is my token of inauguration into the world of CNC machining. What in the world have I gotten myself into??