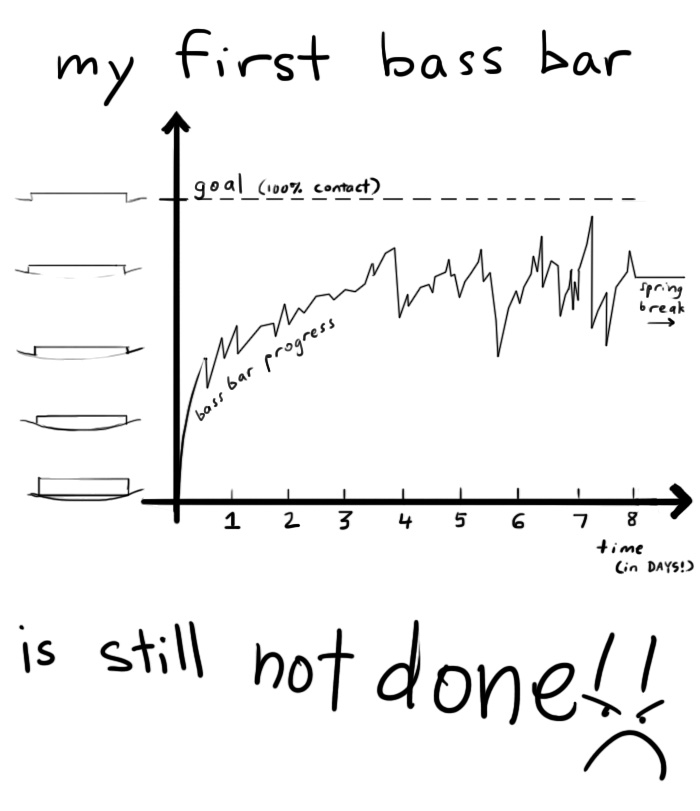

My 2nd trimester at CSVM has ended and I’m on break. Last thing I did was try to finish my bass bar in a huge panic, and well… let’s just say adrenaline is unhelpful for very fine knife work.

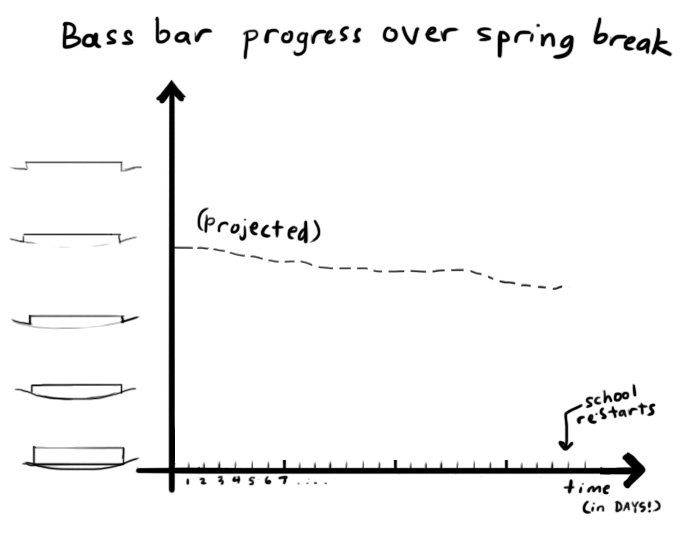

Several upperclassmen recounted horror stories of unfinished bass bars warping and twisting over breaks. This happens to be the LONGEST break we get – 3.5 weeks – and it’s spring, so I know Chicago will go from frozen to warm to thunderstorm to sun several times. Everyone has told me I can’t expect to pick up where I left off before break… and maybe I will have to restart completely!

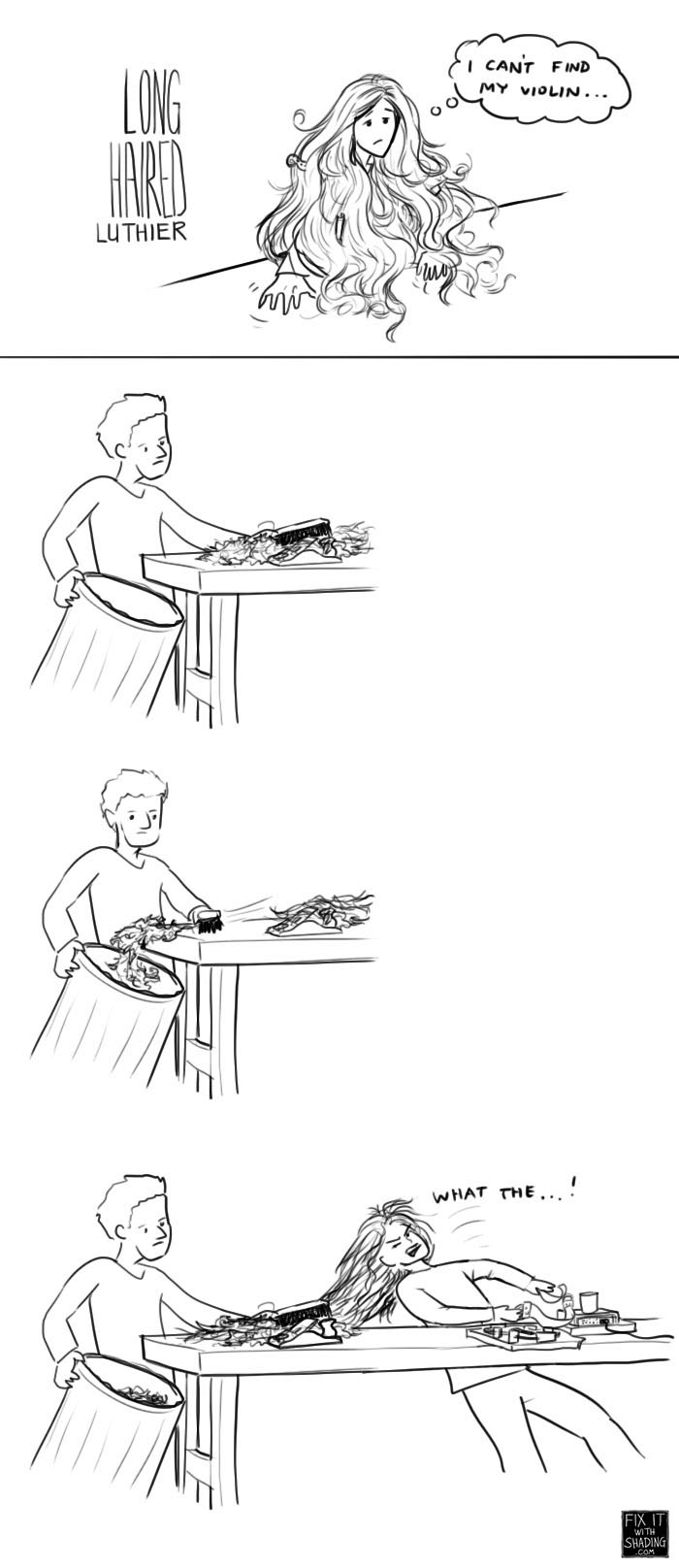

In fact, with all the stories people love to tell, I think now I might be disappointed if I am greeted by anything short of this: