tools

flattening, flattening, and more flattening

New kids have arrived at my school (CSVM), and they are all scrubbing their stones to flatten their stones to flatten their plane soles and sharpen their blades to flatten their first pieces of spruce to make linings. Reminded me of that cumulative song, I know an old lady who swallowed a fly. So here, I present you the violinmaker’s version:

I know an old lady who flattened her straightedge,

but I don’t know how she flattened her straightedge.

She flattened her straightedge to flatten her marble,

she flattened her marble to flatten her whetstone

she flattened her whetstone to flatten her plane sole

she flattened her plane sole to flatten her jointer

she flattened the jointer to flatten her plate edge

but gave it a hollow against her straightedge,

And then she glued.

Note: I confess I took various liberties in accuracy to make the song work better: We do not flatten our straightedges – the way to keep a straightedge flat is… never ever drop it ever. And although we don’t flatten our marbles, we do wiggle our straightedges all over them to find high spots! Oh, and we do not flatten our stones on the marble, though it’s fine to do it that way.

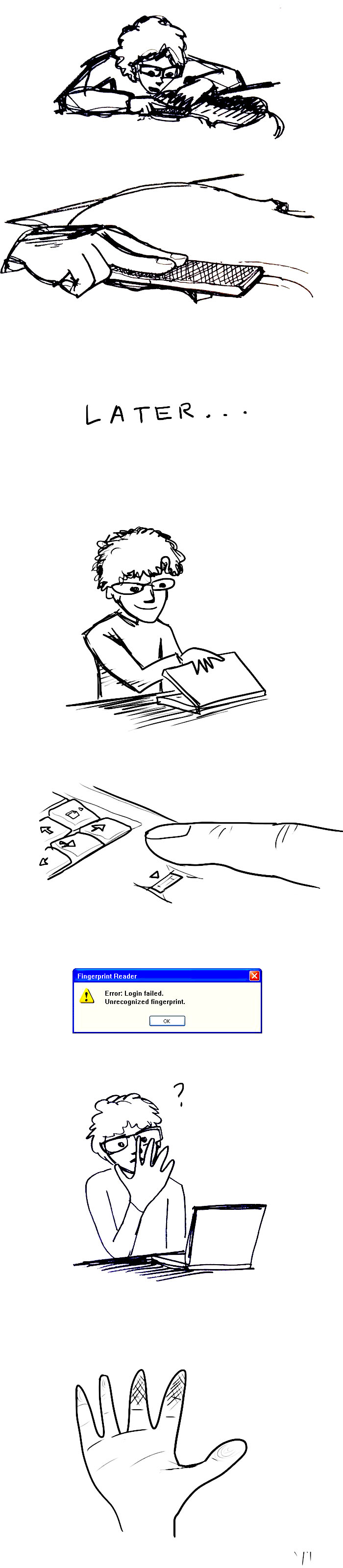

block plane: alternative uses

hammer time

I made a brass hammer!

It is mystery cherry + walnut + maple, made out of leftover slivers of wood from my knife handles. Rounding the stick gives it the saturn rings.

By now, surely you want one too! Well here, I generously offer you instructions on making your own from the Great Violinmaking Notebook of MJ. Steps for laminating your own peanut butter cup racing stripes not included.

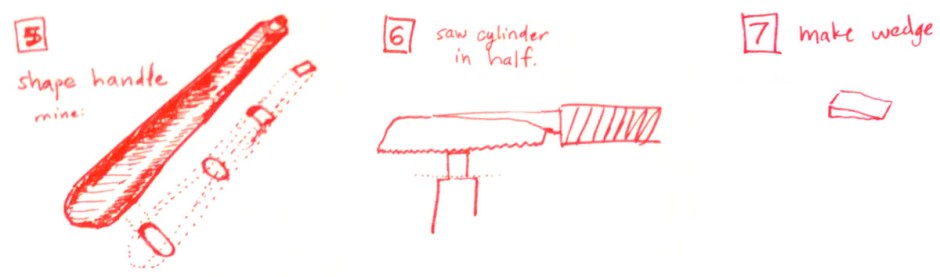

Normal people would use a stick of some nice hard wood that won’t break as you’re banging the hammer around. Abnormal people like me will add several steps of laminating little thin pieces of wood to achieve chocolate stripes. The length of the handle will depend on your hammer head. For my little ~1 cm hammer head, I suggest a handle around 20 cm long.

Score the stick to prevent tearout as you shape the end into a cylinder. The score line should be where the hammer head will sit.

Shape the end into a cylinder to fit the opening of the brass hammer head. Shave corners off up to the score line, alternating between scoring and removing material.

Stop when the shaped end can fit through the narrowest opening in the hammer head (my hammer head had a tapered hole drilled into it).

Shape the handle. I did not want mine completely round, but I wanted it round enough to make the cool effect with the rings. The result was flat ends blending with a round middle.

Saw the cylinder in half.

Make a wedge. It should be wide enough to make up the difference between the two ends of the hammer head’s tapered opening.

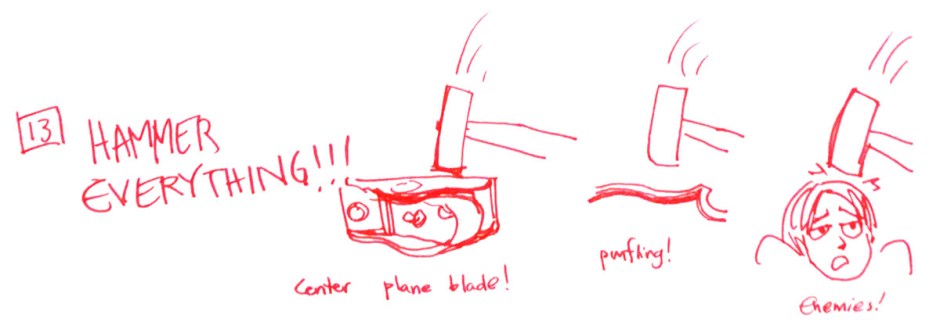

Mix epoxy. Even if you made a very snug joint, as long is it’s a cylinder, the hammer head will eventually want to spin on the handle. So we must fix it in place with epoxy.

Put epoxy in brass hammerhead hole.

Insert stick, clean off goopy mess. It should have squeezed some goo out.

Insert the wedge to pry the two halves of the cylinder apart, causing it to fill up the bigger end of the tapered hole.

Let it set for however long your epoxy’s instructions tell you it should sit for.